In metropolitan collision repair, adhering to stringent industry standards is vital for safety and customer satisfaction. This includes comprehensive staff training in auto mechanics, advanced technologies, hazardous material management, and state-of-the-art facilities. Prioritizing safety involves specialized protocols, regular audits, and best practices. Comprehensive training focuses on emergency preparedness, rapid response, first aid, and workspace operations to minimize risks in a fast-paced urban environment.

In bustling metropolitan areas, efficient yet safe collision repair is paramount. This article delves into the critical safety protocols shaping the landscape of metropolitan collision repair locations. We explore the understanding and implementation of strict industry standards, from ensuring workshops meet essential safety measures to preparing staff for emergency situations. By adhering to these guidelines, metropolitan collision repair facilities not only safeguard workers but also contribute to a seamless and secure automotive service ecosystem.

- Understanding Metropolitan Collision Repair Standards

- Implementing Essential Safety Measures in Workshops

- Training and Preparedness for Emergency Situations

Understanding Metropolitan Collision Repair Standards

In the dynamic landscape of metropolitan collision repair, adhering to stringent industry standards is paramount for ensuring both safety and quality. These standards, developed by leading automotive bodies and regulatory agencies, outline crucial protocols and guidelines that every reputable collision repair shop in urban areas must follow. Understanding these metropolitan collision repair standards involves comprehending not just technical aspects but also the broader implications for public safety and environmental protection.

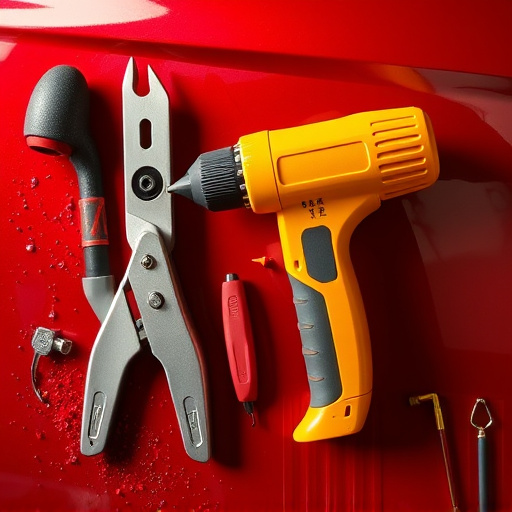

One of the key elements is proper training for staff, encompassing everything from basic auto mechanics to advanced technologies such as computer-aided design (CAD) systems and robotic welding. Additionally, a robust system for managing hazardous materials, including the disposal of old car paint services and other toxic substances, is essential. Customers should expect their collision repair shop to be fully equipped with state-of-the-art facilities that not only facilitate efficient repairs but also uphold safety standards, ensuring every vehicle undergoes rigorous quality checks before it leaves the premises.

Implementing Essential Safety Measures in Workshops

In metropolitan collision repair workshops, implementing essential safety measures is paramount to protect both employees and the environment. These safety protocols extend beyond basic first aid and include specific procedures tailored to the unique challenges of automotive body work. For instance, strict adherence to proper ventilation systems is crucial when handling toxic chemicals used in car paint repair, ensuring air quality and minimizing health risks for workers.

Additionally, proper training on the use of specialized equipment, such as those found in Mercedes-Benz collision repair facilities, is vital. This includes knowledge of emergency shutdown mechanisms, personal protective equipment (PPE), and safe lifting techniques to prevent injuries. Regular audits and updates to safety protocols are essential to stay ahead of industry standards and evolving best practices in automotive body work, ensuring a secure and efficient workplace for all.

Training and Preparedness for Emergency Situations

In the dynamic landscape of metropolitan collision repair, preparedness for emergency situations is paramount. Repair facilities in bustling urban centers often deal with a high volume of vehicles, including luxury vehicle repairs and intricate car body repairs. Therefore, comprehensive training programs are essential to equip staff with the skills to handle unexpected events efficiently. These programs should focus on rapid response protocols, first aid, and the specific challenges unique to metropolitan areas, such as traffic congestion and limited space for operations.

Regular drills and simulations play a crucial role in maintaining readiness. By practicing emergency scenarios, including car paint repair processes during hazardous conditions, teams can enhance their coordination and decision-making abilities. Such training ensures that when an actual crisis arises, whether it’s a chemical spill during a paint job or a sudden structural failure during a collision repair, the facility is prepared to react swiftly and effectively, minimizing potential risks to both personnel and property in these fast-paced metropolitan collision repair settings.

In navigating the complex landscape of metropolitan collision repair, adhering to stringent safety protocols is paramount. By understanding local standards, implementing robust measures within workshops, and ensuring comprehensive emergency preparedness training, repair locations can foster a culture of safety. This not only protects employees and customers but also enhances the overall reputation of the industry, promoting quality and reliability in bustling urban centers.